In addition to the factors mentioned on page 5, you need to understand what the term stopping distance means. Stopping distance consists of three factors:

Driver’s reaction time + Brake lag + Braking distance.

Reaction time

The time it takes from the moment a hazard is recognized to the time the brake pedal is applied, approximately 3/4 of a second to 1 1/2 seconds.

Brake lag

The time air takes to travel through a properly maintained air brake system, about 4/10 of a second.

Braking distance

The actual distance a vehicle travels after the brake is applied until the vehicle stops. This distance depends on the ability of the lining to produce friction, the brake drums to dissipate heat and the tires to grip the road.

Professional drivers never take brakes for granted. The braking system must be tested and adjustment checked before placing a vehicle into service. Professionals understand the braking system, realize its capabilities and limitations, and learn to use it to their advantage.

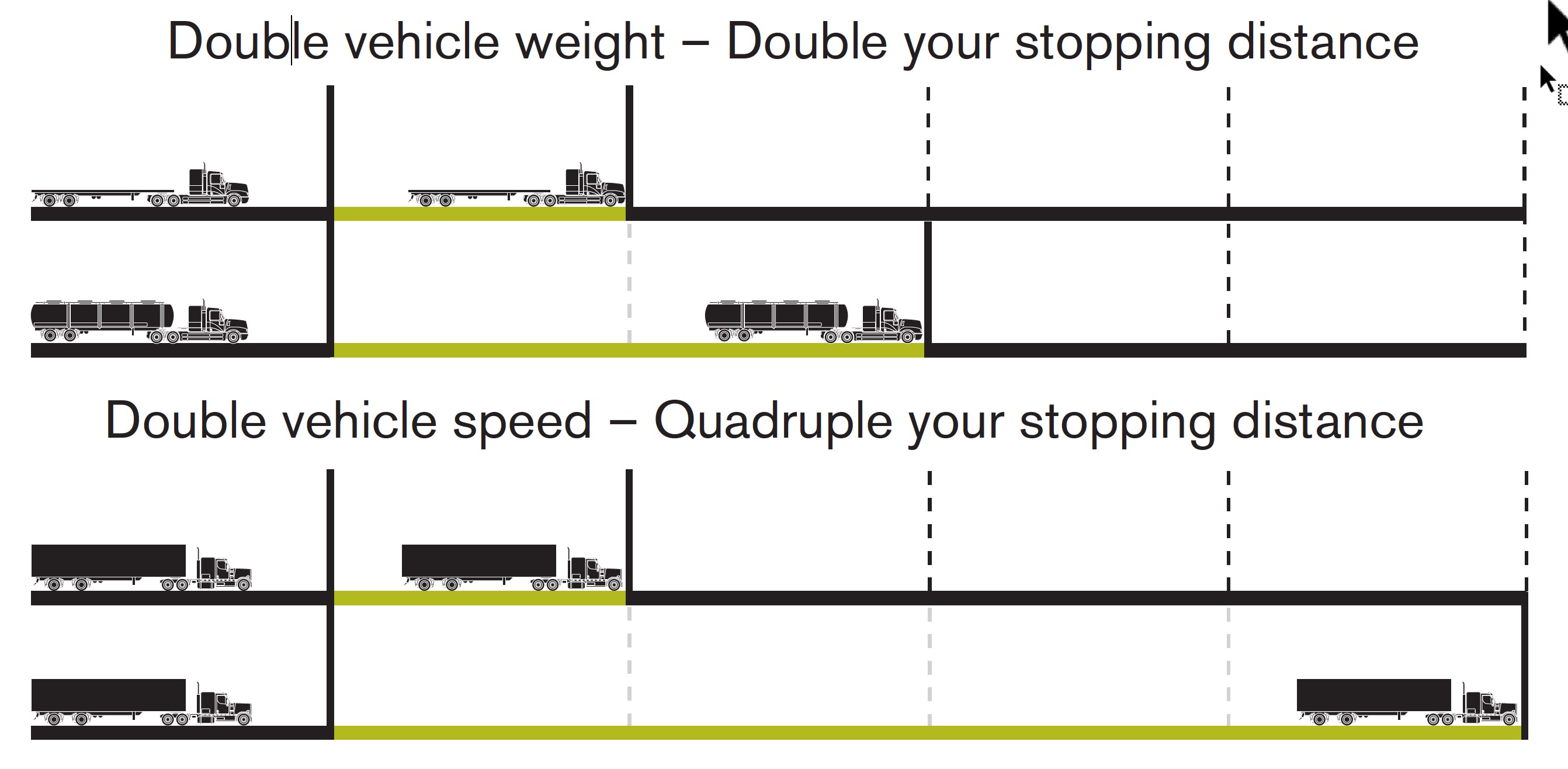

Heavy vehicles require powerful braking systems that are obtained by use of mechanical leverage and air pressure. Brakes must be used keeping in mind the heat generated by friction. If heat becomes too great, braking effectiveness will be lost. The heavier the load and the faster the speed, the greater the power needed to stop (Fig. 7). The professional driver is well aware that the vehicle, even with properly adjusted brakes, will not stop as quickly as a passenger vehicle.